Scegliere spideREX K8 significa scegliere il meglio.

Perché non tutti i cappotti sono uguali.

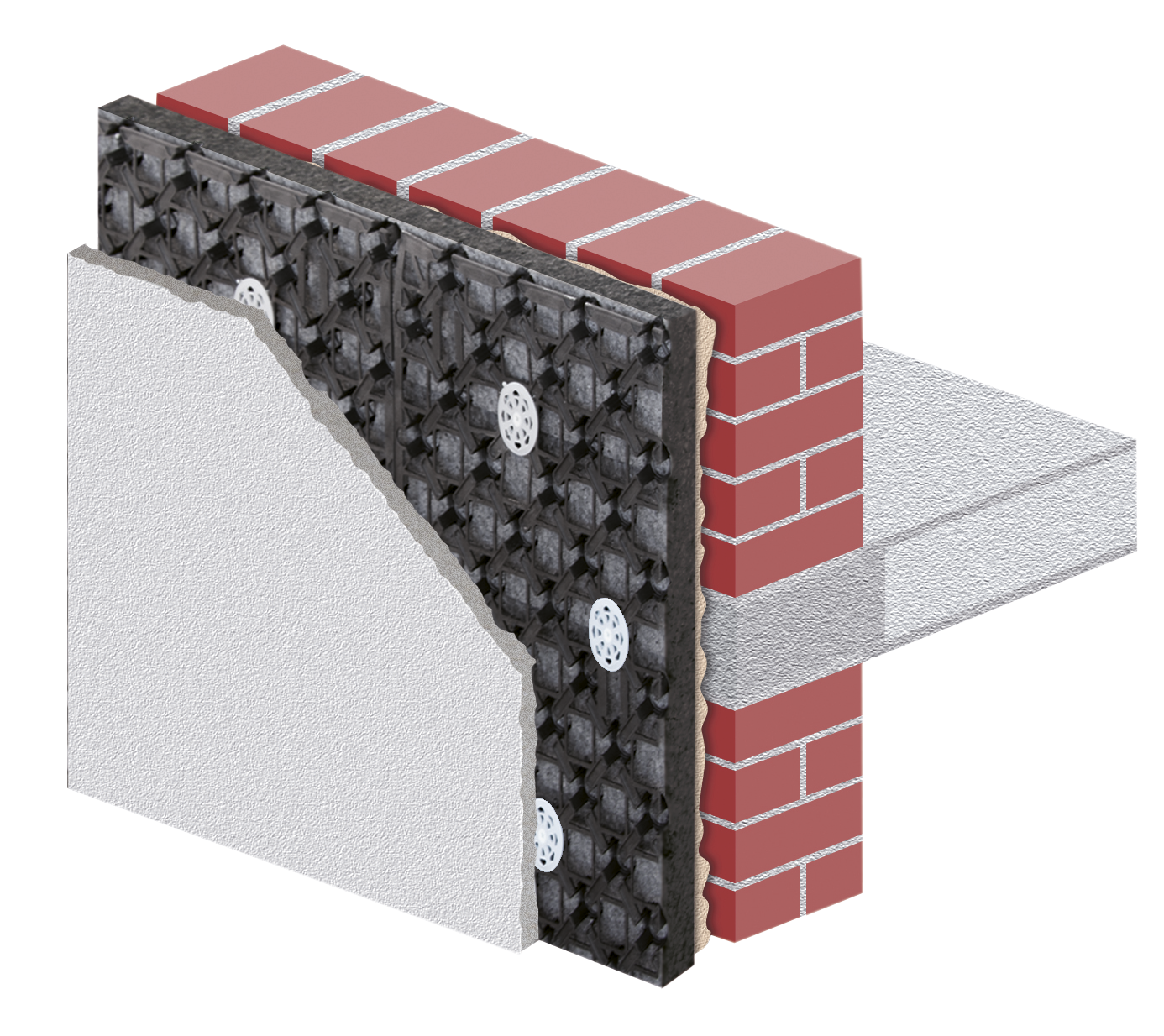

spideREX K8 è il sistema cappotto sicuro brevettato da Rexpol che rivoluziona il tradizionale concetto di cappotto termico per edifici. È un sistema innovativo di isolamento delle facciate, costituito da una speciale lastra termoisolante in EPS con applicata una rete tridimensionale di armatura porta intonaco, predisposta per il fissaggio meccanico, che permette la spruzzatura meccanizzata di intonaci speciali, mantenendone lo spessore uniforme e calibrato, e garantendo altissime prestazioni tecniche unite alla massima velocità di posa in opera del sistema.

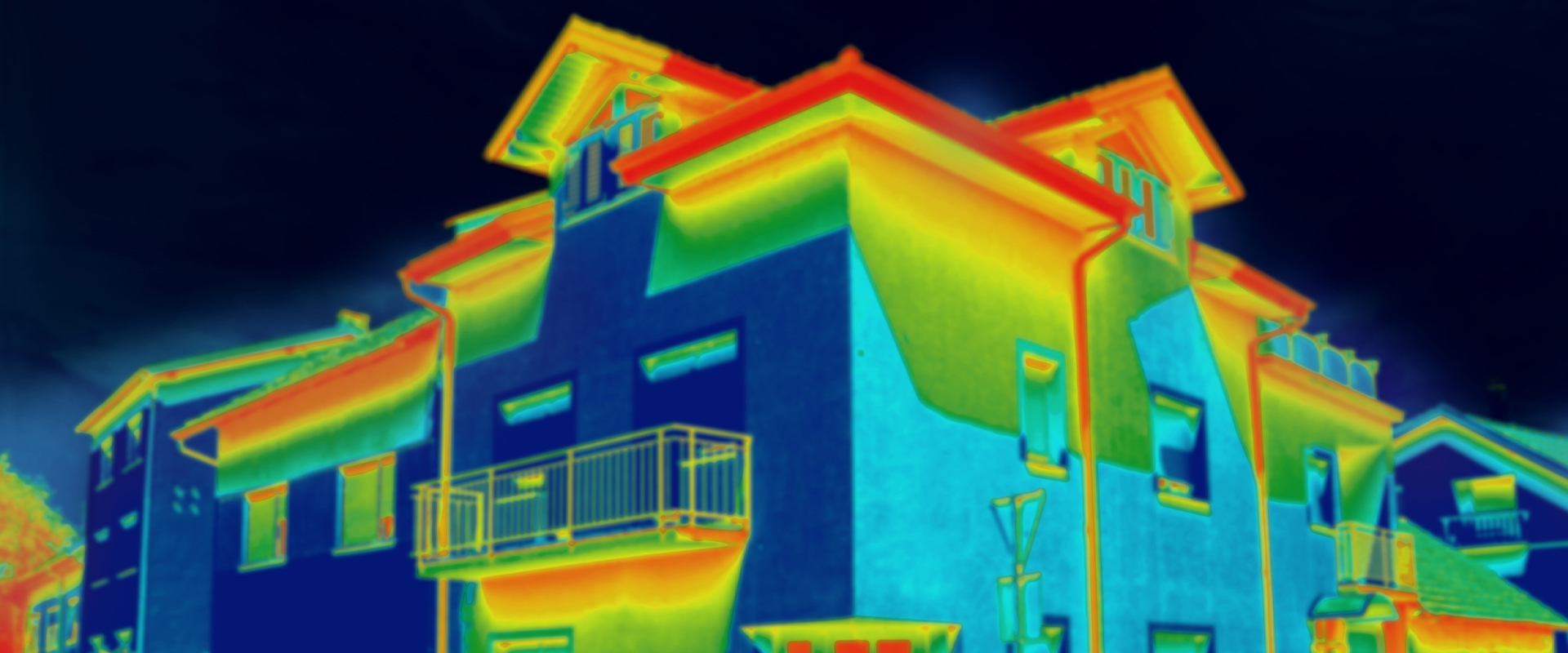

- maggior sfasamento termico, miglior isolamento

- miglioramento delle prestazioni meccaniche

- maggior resistenza al fuoco

- miglioramento acustico

- maggior sicurezza in caso di sisma

- facilità di installazione

- comprovata sostenibilità ambientale certificata EPD®

- piena rispondenza ai criteri CAM

Studiato per fornire prestazioni al top

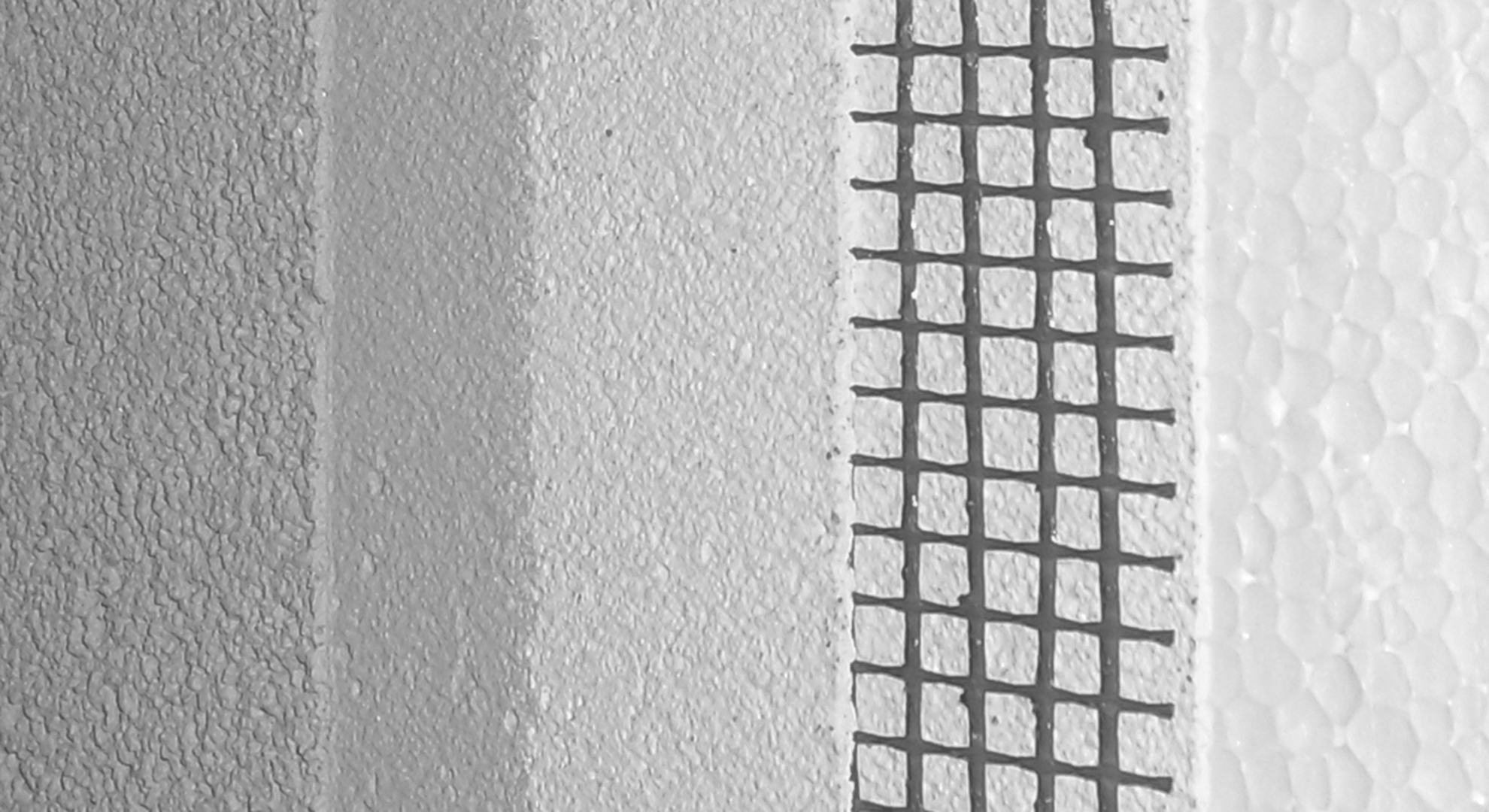

spideREX K8 a differenza dei cappotti tradizionali, in cui il rasante che ricopre le lastre isolanti ha uno spessore di 5/6 millimetri, grazie alla rete tridimensionale applicata garantisce uno spessore calibrato di intonaco di 25 millimetri, che abbraccia l'edificio senza interruzioni.

Lo spessore dell'intonaco, unito alla capacità isolante dell'EPS offre altissime performance.

Sezione di una parete con l'applicazione di spideREX K8, dove è ben visibile lo spessore dell'intonaco di oltre 25 mm

Sezione di una parete con l'applicazione di cappotto di tipo tradizionale: lo spessore del rasante è di circa 5 mm

UN POKER VINCENTE DI APPLICAZIONI

UNA SOLUZIONE PER OGNI PROBLEMA DI ISOLAMENTO

spideREX K8

CLASSIC

Rivestimento

colorato a spessore

spideREX K8

STRONG

Rivestimento

ceramico lapideo

spideREX K8

EVOLUTION

Cappotto

su cappotto